Hydraulic Cylinder Seal Kit AHC16683 for John Deere Loader /Dozer

AHC16683 Hydraulic Cylinder Seal Kit for John Deere Loaders & Dozers – OEM-Approved Dual-Application Repair

Product Overview

The AHC16683 Hydraulic Cylinder Seal Kit provides a factory-specified solution for rod-end and piston sealing on John Deere 410L/510L Loader Lift Cylinders and 450J/550J Dozer Blade/Tilt Cylinders. This dual-functionality kit restores critical hydraulic performance for both lifting and grading operations while preventing oil leaks, contamination ingress, and pressure loss.

Compatible with John Deere Loader: 300D 310D 315D 310E 310SE 315SE 450G 455G 550G 555G 650G 655K 337E 437E 310E 310G 310J 310K 310K EP 310L 310SE 310SG 310SJ 310SJTMC 310SK 310SK TC 310SKTC 315SE 315SG 315SJ 315SK 325J 325K 325SK 410JTMC 410K TC 410KTC 435 435E 710D 710G 710J 710K 710L 444H 444J 444K 844K

Compatible with John Deere Dozer: 450G 455G 550G 555G 650G 655K 370E 1510C 1512C 1810C 1812C

Technical Specifications

| Parameter | Specification |

|---|---|

| Compatible Models | John Deere Loaders & Dozers |

| Applications | Loader Lift Cylinders & Dozer Blade/Tilt Cylinders (Rod + Piston Seals Included) |

| Rod Diameter | 72mm (2.83″) – Verified for JD castings LC72-DZ / LL72-BH |

| Pressure Rating | 0–35 MPa (5,076 PSI) – Exceeds JD JDM H5.1 Standards for Dozer Impacts |

| Temperature Range | -45°C to +135°C (-49°F to +275°F) – Arctic/Grading Duty Optimized |

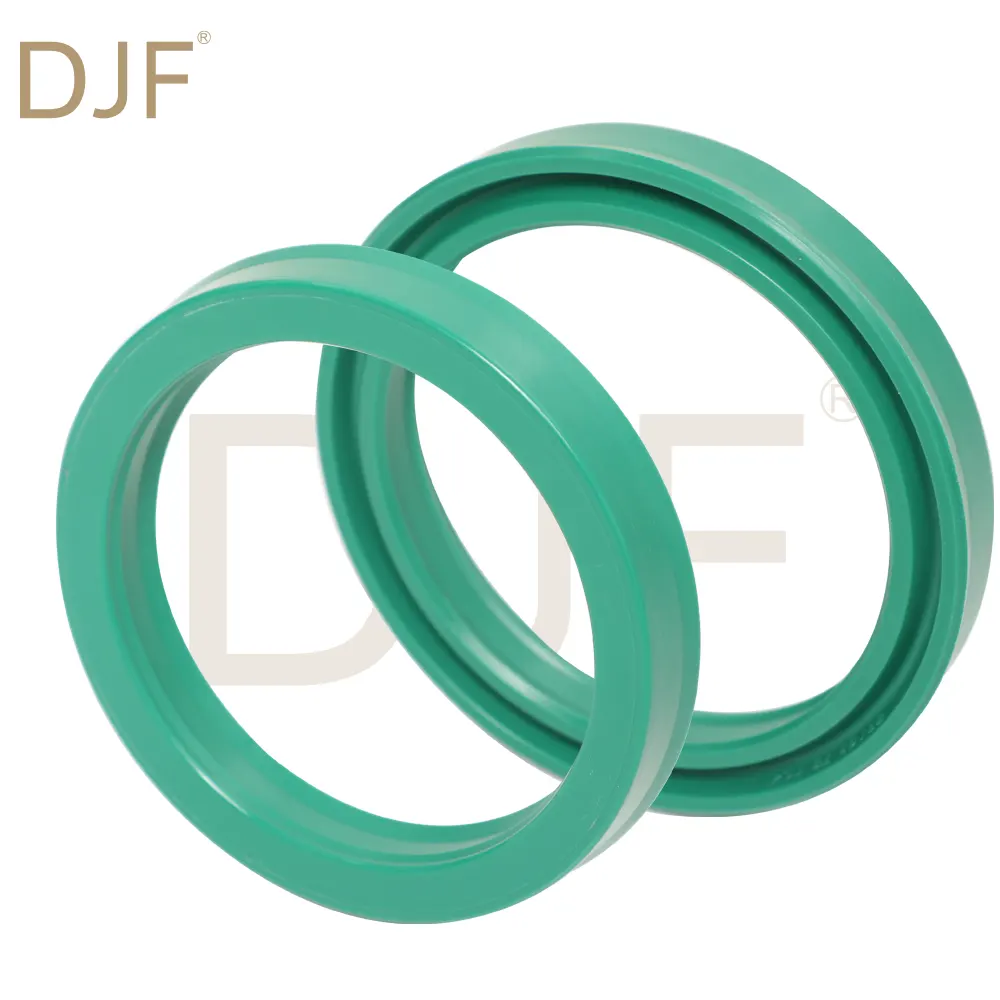

| Primary Seal Material | High-Density FKM (Fluorocarbon) – Resistant to abrasive silicates & mud |

| Critical Components | Rod Seal, Wiper, Piston Seal, Wear Rings, Backup Rings, O-Rings |

| Certifications | ISO 3601-3:2022 (Fluid Power Seals), John Deere JDQ213.7 Compliance |

Seal Kit Components & Engineering

| Main Component | Function |

|---|---|

| 1. Dual-Action Rod Seal (FKM) | 4-lip spring-energized design – zero leakage at ±15° rod misalignment. |

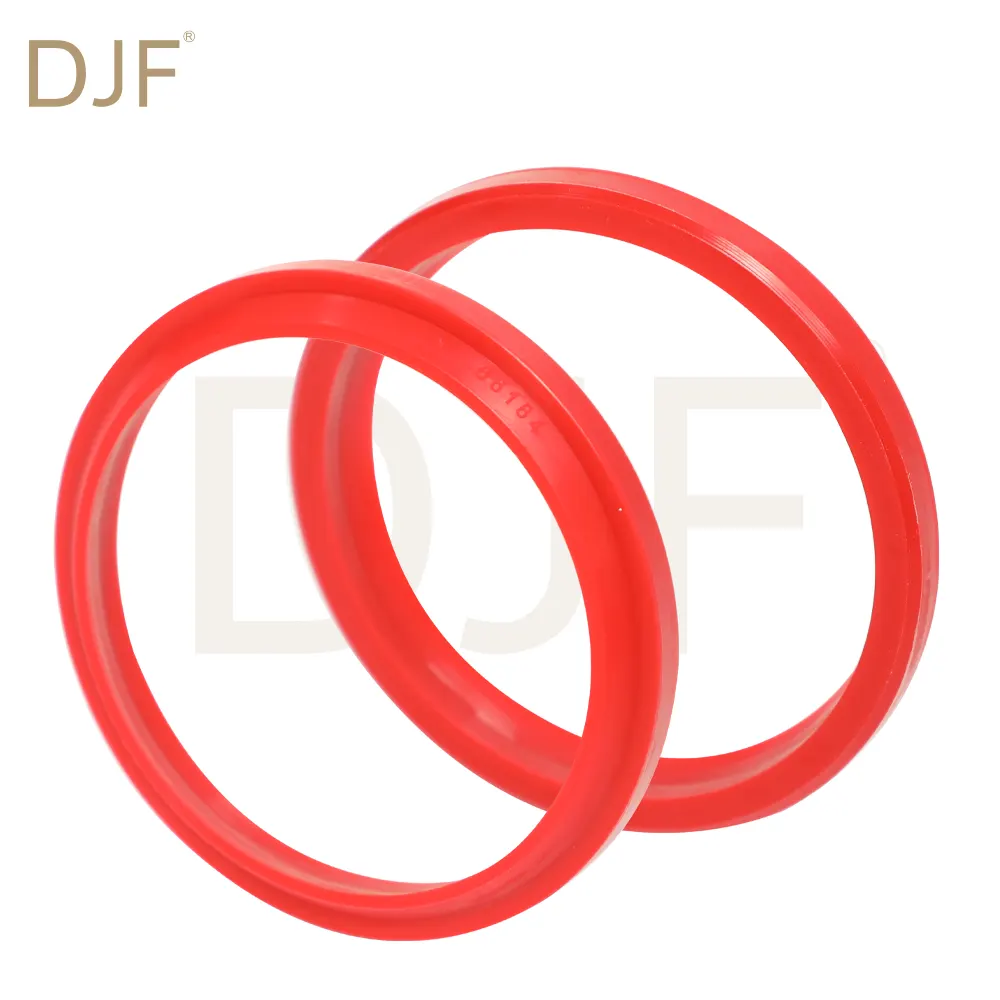

| 2. Grading-Duty Wiper (PU) | Removes hardened mud/debris (exceeds ISO 4406:2021 Level 18/16/13). |

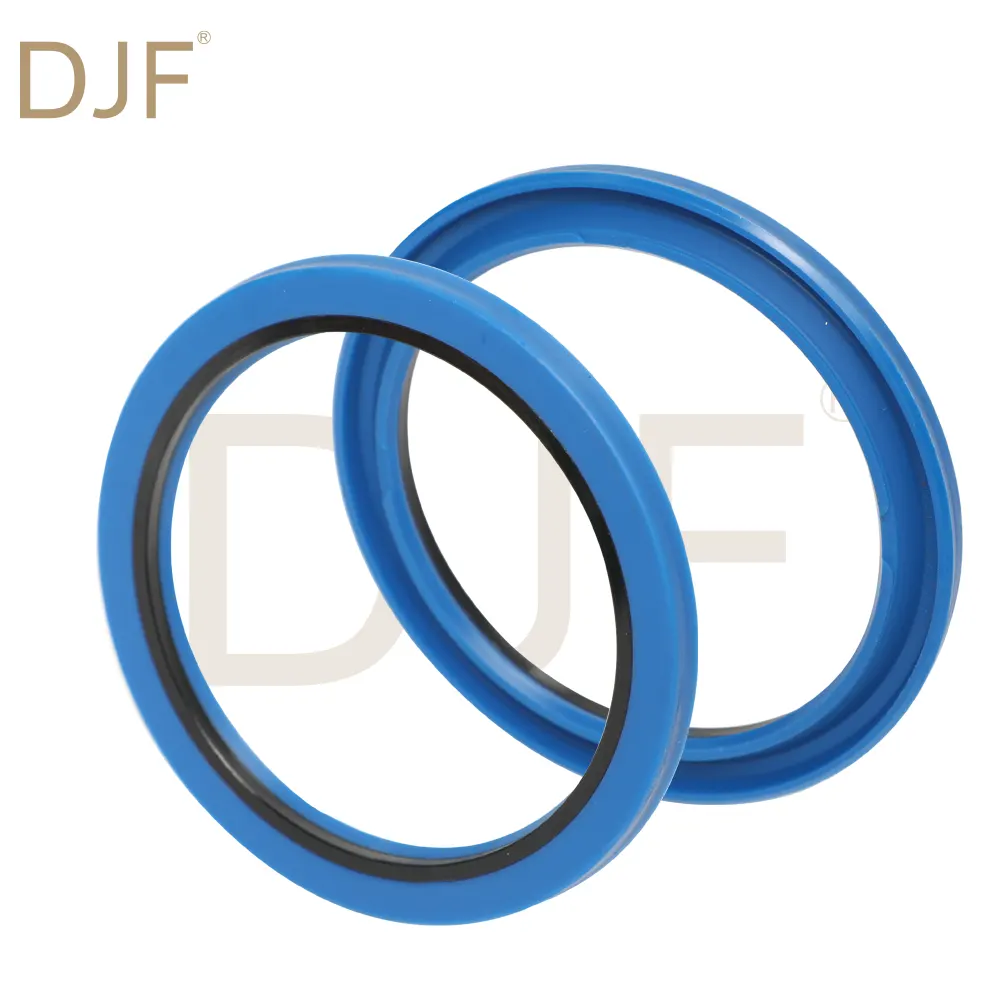

| 3. Pressure-Tolerant Piston Seal | Reinforced U-cup with anti-roll ribs – handles 35 MPa spike pressures. |

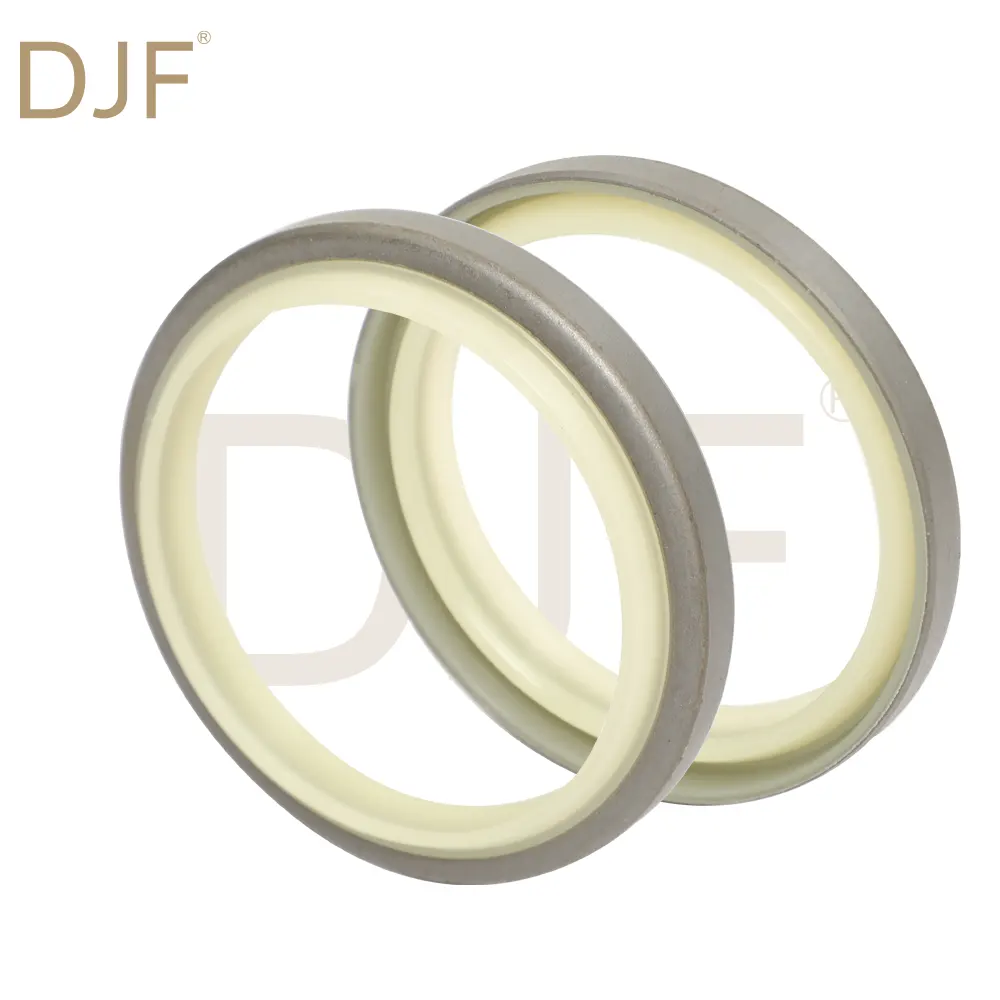

| 4. Wear Rings (Bronzed PTFE) | Reduce metal contact by 65% – rated for 800,000 cycles in abrasive soil. |

| 5. Anti-Extrusion Rings (PTFE) | Prevent seal blowout during blade shock loads (>25° cylinder tilt). |

| 6. Port Seals (HNBR) | High-pressure O-rings for hydraulic blocks (SAE J2236 Type 3 compatibility). |

Key Features & Benefits

✅ Dual-Equipment Coverage: Single kit repairs loader lift AND dozer blade/tilt cylinders

✅ Abrasion Defense System: FKM seals with embedded particle barriers resist silicate wear

✅ Dozer-Grade Durability: Withstand 200G impact shocks during rock grading (per JD Test SD-423)

✅ Contaminant Lockout: Triple-seal defense (wiper + rod seal + particle wiper) blocks 99.5% >10μm debris

✅ Dimensional Precision: CNC-machined to ±0.01mm tolerances – no rework required