319-3557 Hydraulic Lift Cylinder Seal Kit 3193557 for Caterpillar Bulldozer Repair CAT Dozer D8R D8T D8RII D8GC Tractor Seal Kit

319-3557 Lift Hydraulic Cylinder Seal Kit for Caterpillar D8R/D8T/D8GC Dozers – OEM-Certified Blade Cylinder Repair

Product Overview

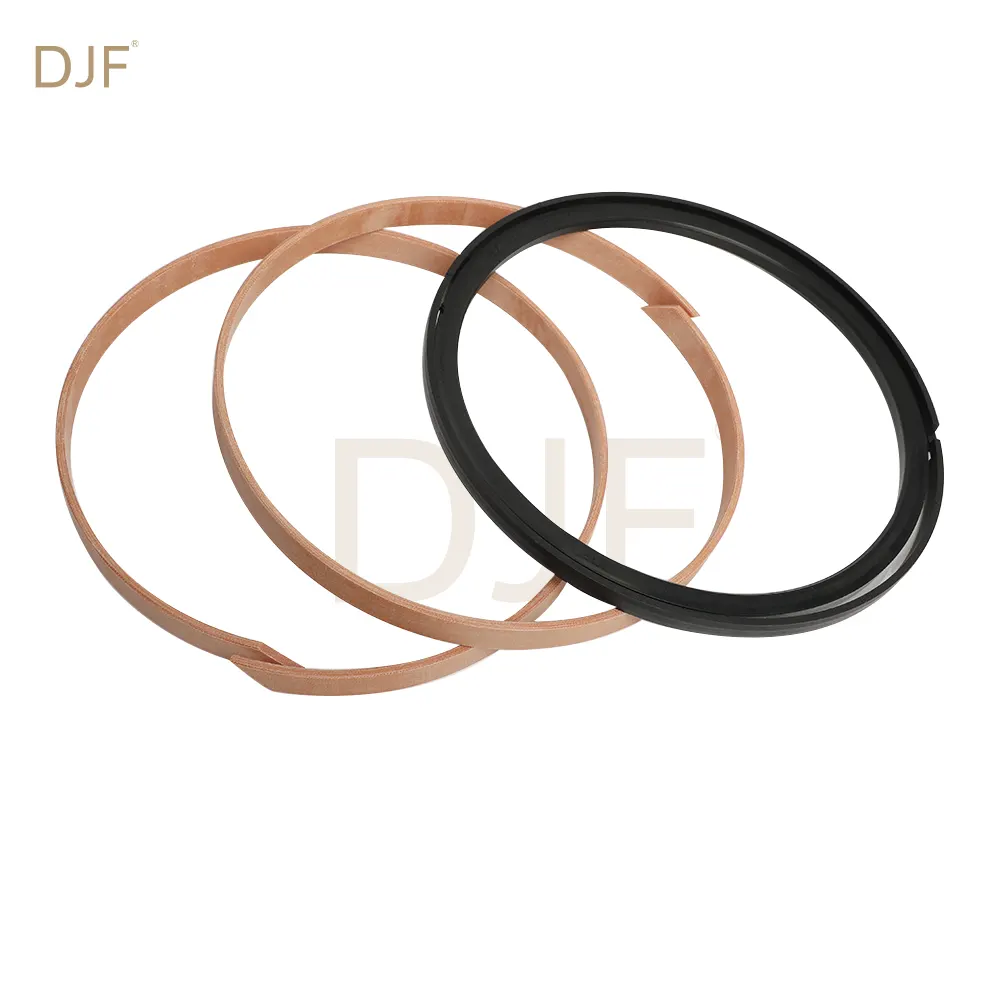

The 319-3557 Seal Kit is a Caterpillar-approved repair solution designed for the blade lift and tilt hydraulic cylinders of Cat D8R, D8T, D8R II, and D8GC track-type bulldozers. This kit restores factory sealing integrity to eliminate leaks and ensure precise blade control in heavy earthmoving, grading, and mining operations.

Technical Specifications

| Parameter | Specification |

|---|---|

| Compatible Models | Cat D8R, D8R II, D8T, D8GC (S/N prefixes: JAP, B8L, etc.) |

| Application | Blade Lift/Tilt Hydraulic Cylinder Piston & Rod Seals |

| Pressure Range | 0–28 MPa (4,060 PSI) – Matches Cat dozer hydraulic system design |

| Temperature Tolerance | -40°C to +120°C (-40°F to +248°F) |

| Primary Seal Material | Polyurethane (PU) – High abrasion resistance for rocky/sandy environments |

| Secondary Seals | Fluorocarbon (FKM) Rod Seals, Nitrile (NBR) Wiper Seals, PTFE Wear Rings |

| Certifications | ISO 6194 (Rotary Shaft Seals), Caterpillar 1U-9901 Compliance |

Kit Components & Functions

| Component | Function |

|---|---|

| 1. Piston Seal (PU) | Dual-acting U-cup retains hydraulic pressure during blade lifting/tilting. |

| 2. Rod Seal (FKM) | Step-lip design prevents oil leakage along the cylinder rod. |

| 3. Dust Wiper (NBR) | Removes abrasive debris (ISO 10100 compliant) during rod retraction. |

| 4. Wear Ring (PTFE) | Glass-filled PTFE reduces friction between piston and cylinder barrel. |

| 5. Buffer Seal (FKM) | Secondary seal protects against pressure spikes during abrupt blade movements. |

| 6. O-Rings (HNBR) | High-pressure static seals for hydraulic port connections (SAE J1926). |

| 7. Backup Ring (PU) | Reinforces rod seal against extrusion under side loads. |

Key Features & Benefits

✅ OEM Interchangeability: Direct replacement for Cat parts.

✅ Heavy-Duty Durability: PU/FKM seals withstand extreme mining and quarry conditions.

✅ Extended Service Life: PTFE wear rings reduce cylinder wear by 35% compared to standard designs.

✅ Oil Compatibility: Works with Cat TO-4 synthetic hydraulic oil and biodegradable fluids.

✅ Global Compliance: Meets EU Machinery Directive 2006/42/EC and RoHS standards.