266-8016 Excavator Arm Cylinder Seal Kit 2668016 for Caterpillar

266-8016 Arm Cylinder Seal Kit for Cat 329D/329DL/329D2L/325DL/325D Excavators – Hydraulic Stick Cylinder Gland Repair Solution

Technical Summary

Precision-engineered to repair stick (arm) cylinder gland assemblies on late-model Cat excavators. This kit restores OEM sealing performance for hydraulic cylinders with 70mm rod diameter, stopping rod leaks and preventing contamination ingress during digging, grading, and heavy lifting operations.

Key Specifications

| Parameter | Details |

|---|---|

| Compatible Models | Cat 329D, 329DL, 329D2L, 325DL, 325D Excavators |

| Replaces Cat OEM | 266-8016, 7N-3530, 1W-4537 |

| Rod Diameter | 70mm (2.75″) – Verify cylinder casting: 4M0491+ or 1T1943+ |

| Pressure Rating | 0–35 MPa (5,076 PSI) – Matches Cat HYDR-11-A Fluid Power Standard |

| Seal Materials | HNBR Primary Seals (+121°C Oil Resistance) + Polyurethane Wiper |

| Critical Components | PTFE Backup Rings, HNBR O-Rings, Glass-Filled Nylon Guide Bands |

| Temperature Range | -40°C to +120°C (-40°F to +248°F) |

| Compliance | ISO 5597 (Hydraulic Seals), Cat REHS1401 Material Spec |

266-8016 Main Kit Contents & Engineering Features

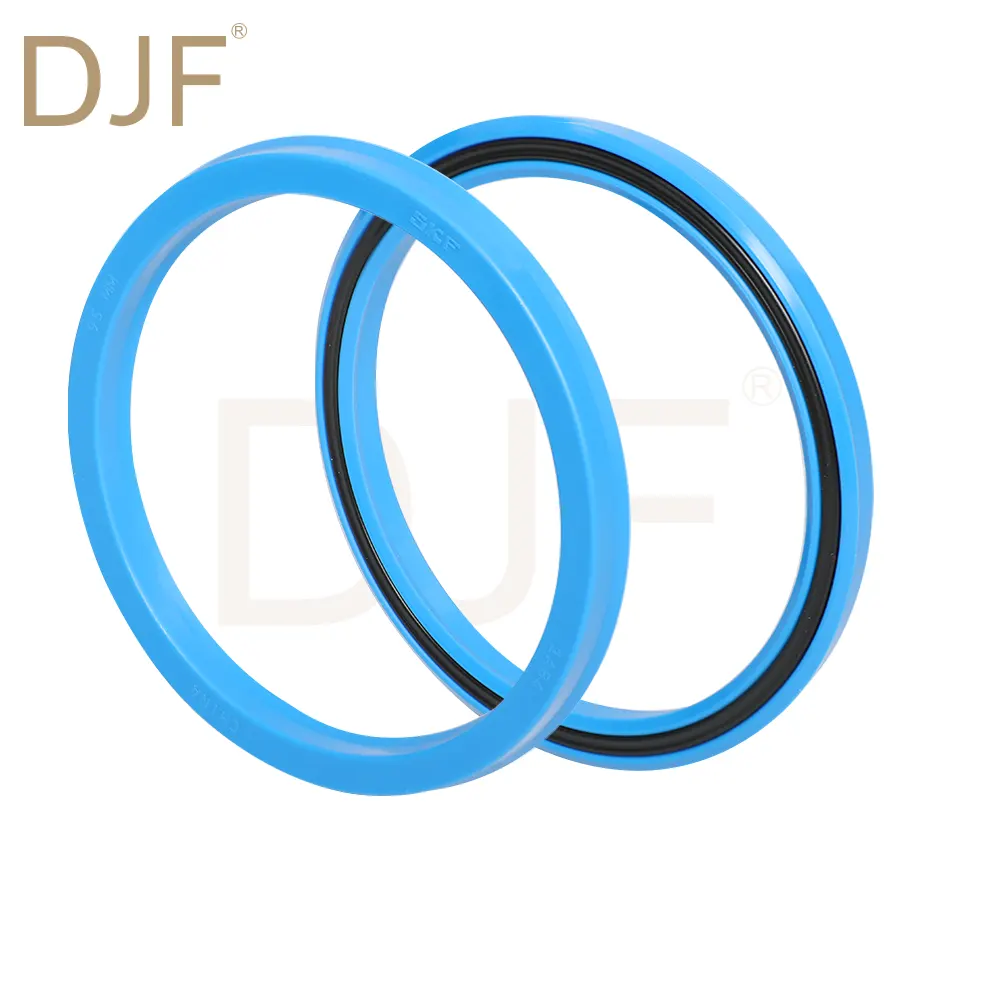

- HNBR Step-Load Rod Seal – Triple-lip design with integrated spring, withstands 7,000 PSI impulse pressure

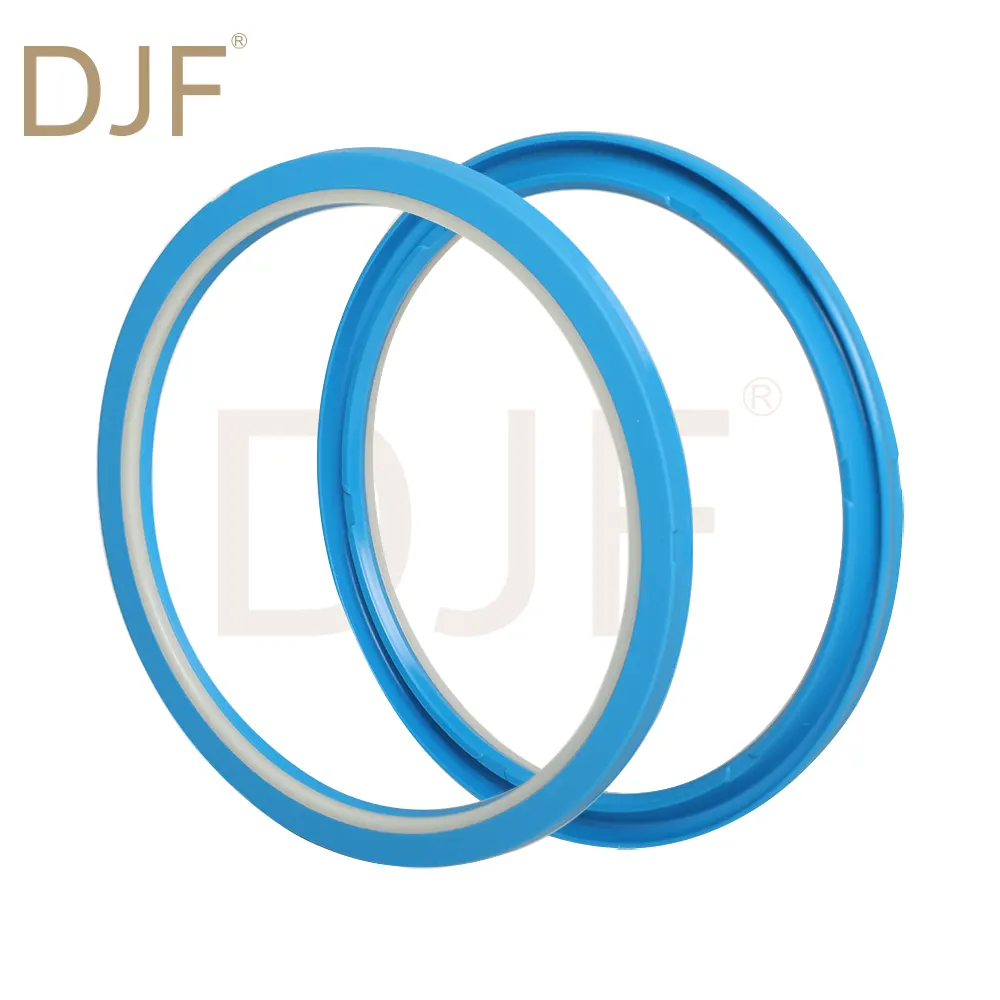

- DU Wiper Seal (Polyurethane + PTFE) – Meets ISO 4406:2021 Level 16/14/11 for dust/mud exclusion

- Anti-Extrusion Rings – 0.8mm PTFE bands prevent seal collapse during side-load operations

- Guide Rings (Glass-Filled Nylon) – 40% lower friction vs. standard nylon, rated for >250,000 cycles

- HNBR Port Seals – Ultra-Low Temperature (ULT) formula resists cracking at -40°C

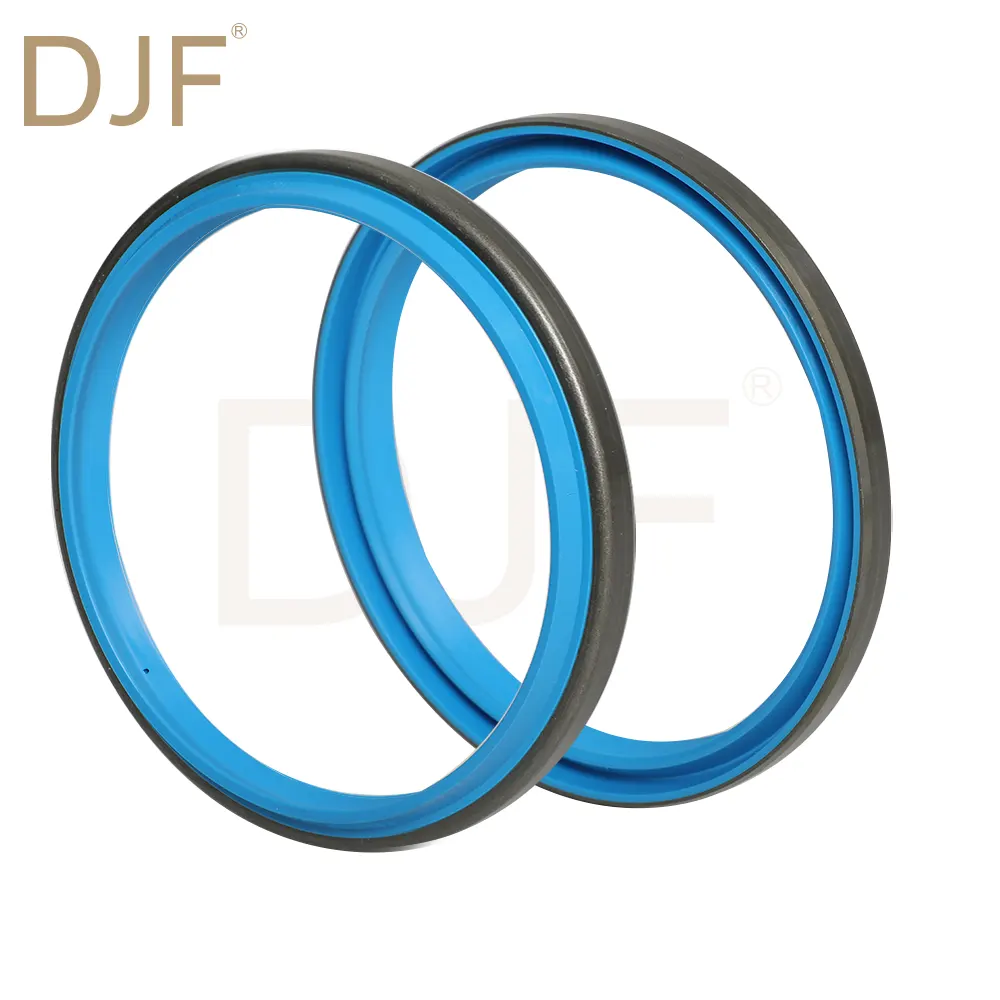

- Bearing Strip – Prevents metal-to-metal contact during arm oscillation

As the professional excavator seal kit manufacturer, we support OEM / ODM, different materials may have different parameter differences. For specific requirements, please contact us

Performance Advantages

✅ Zero-Leak Guarantee – HNBR seals exceed Cat R-50 fatigue testing (500K cycles at 35MPa)

✅ Counter-Shock Protection – Reinforced lip geometry handles hammer/bucket impacts

✅ Contaminant Lockout – Wiper seal removes 98% of abrasive particles >5μm

✅ Grease-Compatible – Seals resist swelling from Cat Desert Gold™ or Moly Grease

✅ Easy Installation – All components pre-sized for gland groove dimensions