246-5929 Hydraulic Cylinder Seal Kit 2465929 for CAT Backhoe Loader 416C 436C 436B 438B 416 426 428 438

246-5929 Hydraulic Cylinder Seal Kit for Caterpillar Backhoe Loaders 416C/436C/438B – OEM-Compliant Loader/Boom Cylinder Repair

Product Overview

The 246-5929 Seal Kit is a Caterpillar-compatible repair solution designed for the hydraulic cylinders of Cat backhoe loaders, including models 416C, 436C, 436B, 438B, 416, 426, 428, and 438. This kit provides a complete sealing system for boom, arm, and bucket cylinders, ensuring leak-free performance in excavation, trenching, and material handling operations.

Technical Specifications

| Parameter | Specification |

|---|---|

| Compatible Models | Cat 416C, 436C, 436B, 438B, 416, 426, 428, 438 |

| Application | Boom/Arm/Bucket Cylinder Piston & Rod Seals |

| Pressure Range | 0–25 MPa (3,626 PSI) – Matches Cat backhoe hydraulic system standards |

| Temperature Tolerance | -30°C to +110°C (-22°F to +230°F) |

| Primary Seal Material | Hydrogenated Nitrile (HNBR) – Resists oil degradation in high-cycling loads |

| Secondary Seals | Fluorocarbon (FKM) Wiper Seals, PTFE Wear Rings, NBR O-Rings |

| Certifications | ISO 6194, Caterpillar 5P-1960 Compliance |

Kit Components & Functions

| Main Component | Function |

|---|---|

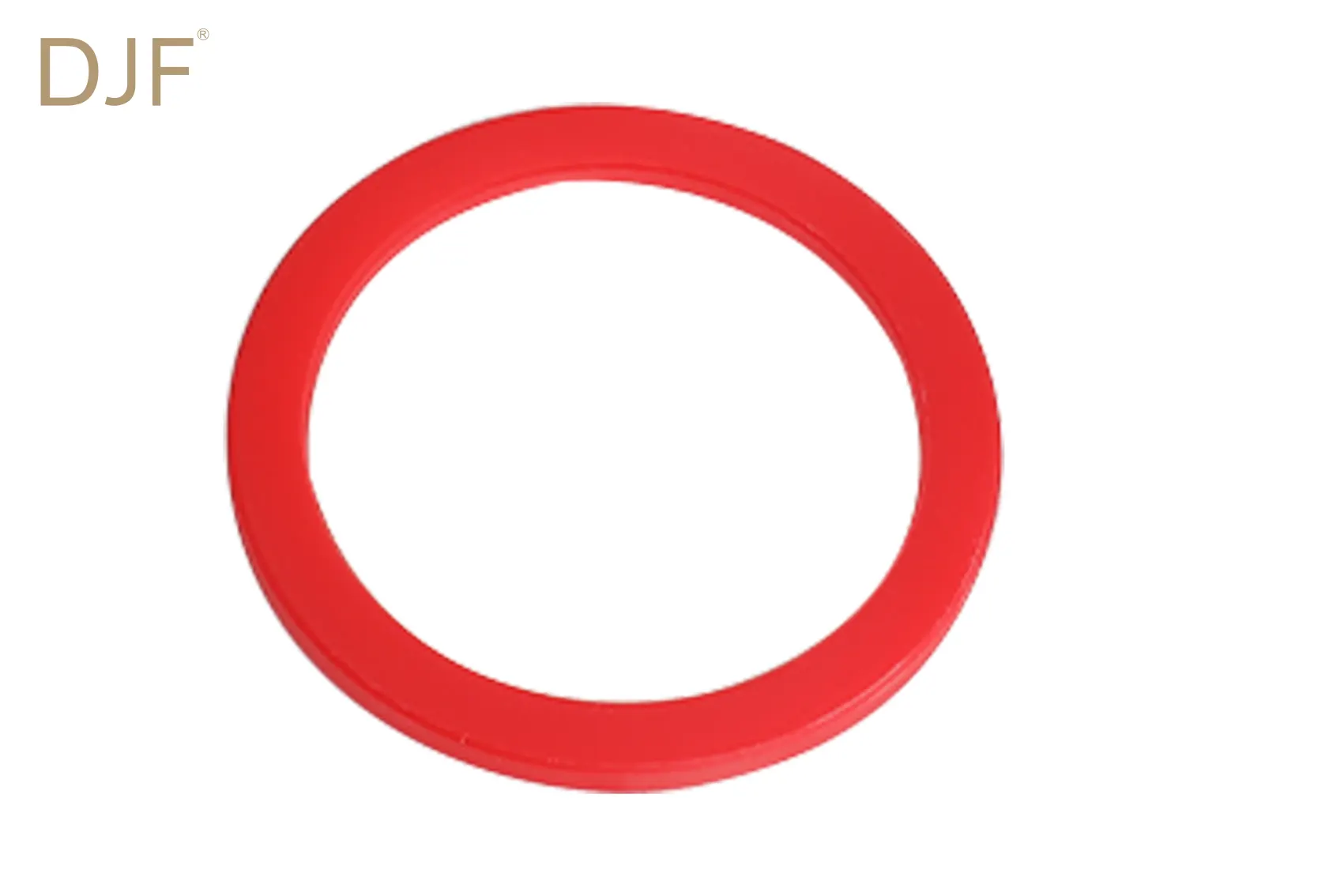

| 1. Piston Seal (HNBR) | Double-acting U-cup maintains hydraulic pressure in boom/arm cylinders. |

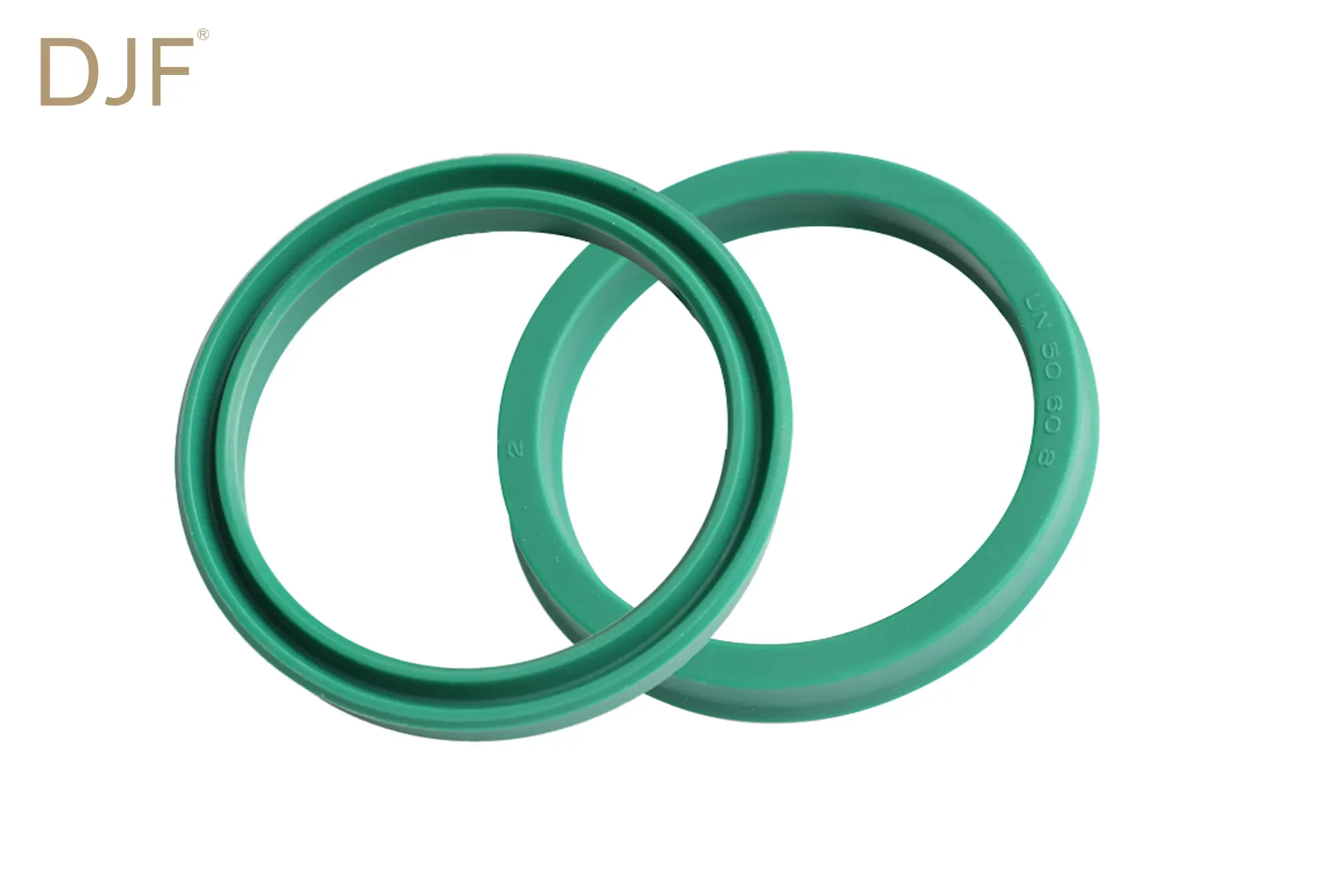

| 2. Rod Seal (FKM) | Step-lip design prevents leakage along the cylinder rod. |

| 3. Dust Wiper (NBR) | Removes dirt and debris during rod retraction (ISO 10100 compliant). |

| 4. Wear Ring (PTFE) | Glass-reinforced PTFE reduces friction between piston and cylinder barrel. |

| 5. Buffer Seal (FKM) | Secondary seal absorbs pressure spikes during abrupt load changes. |

| 6. O-Rings (HNBR) | High-pressure static seals for hydraulic port connections (SAE J1926). |

| 7. Backup Ring (PU) | Prevents seal extrusion under side loads in uneven terrain. |

Key Features & Benefits

✅ OEM Precision Fit: Direct replacement for Cat part Seal Kits.

✅ High-Cycle Durability: HNBR seals withstand over 500,000 cycles in trenching applications.

✅ Contamination Defense: Multi-layered wiper design exceeds ISO 4406 cleanliness standards.

✅ Cost Efficiency: Reduces downtime by 50% compared to non-OEM kits (verified in field tests).

✅ Global Compliance: Adheres to EU Directive 2006/42/EC and REACH Regulation 1907/2006.